The Oliver Guide to Sustainable Packaging

Contents

Introduction

The need for ecological sustainability in business practices and products has never been more clear. This is true regardless of industry, but especially for printing and packaging companies.

Sustainable companies commit to achieving zero manufacturing waste at their facilities, reducing their carbon footprint, and working with customers to produce packaging that reduces raw material requirements and maximizes recycling or reuse.

By investing in these initiatives, printing and packaging manufacturers enable you to pursue your own sustainability goals. Embracing sustainable packaging is a major way your company can go green and become an industry leader.

This guide covers everything you need to know about sustainable packaging, from its basic definition to dispelling recycling myths, incorporating eco-friendly materials and practices, appealing to consumers who value green products, and more.

Use the guide to take the next step in your sustainability journey.

What Is Sustainable Packaging?

Sustainable packaging achieves its intended role while minimizing resource requirements, using responsibly sourced materials, and maximizing opportunities for recovery, recycling, or reuse.

Sustainability will continue to be a central factor within the printing and packaging ecosystem for any socially conscious company. In fact, the biggest brands in the world (particularly those in the health and beauty or food and beverage industries) continue to set initiatives to achieve sustainable goals, whether that’s reducing their use of plastics or implementing more recycled materials.

If your packaging is to become more sustainable, you need to consider not only the materials used, but what happens to them once they’re opened and discarded by consumers, as well as the energy expended in creating them.

That requires the help of experts. Have conversations internally about what you’d like to accomplish. Then seek the guidance of experienced packaging manufacturers. Chances are you’ll learn not just about your options, but also the advantages of implementing a sustainable packaging strategy.

Advantages of Sustainable Packaging

You may be surprised at how many of your larger packaging goals can be accomplished when you emphasize sustainability.

Green packaging provides several significant benefits for your brand:

Right-size packaging saves you money. Not only does using unnecessary amounts of material result in more waste, but it’s expensive. More money is spent on printing to ensure visuals maintain the proper composition on packaging. Heavier and bulkier packaging turns into higher shipping costs. Right-size packing corrects against that (and more).

A dozen square inches of superfluous paperboard or plastic wrap per product quickly adds up when you’re moving several thousand items a month. An additional ounce per product really inflates transportation costs. And then there’s the air tax, where you are literally paying to ship air because you haven’t bothered to remove excess space from your packaging.

Reduce your carbon footprint. Sustainable packaging provides a key pathway for brands to shrink their carbon footprints—and step up their action on climate change.

Each stage of the production and shipping process contains an opportunity to reduce carbon emissions. Minimizing the use of fossil fuels means cutting down on plastics as much as cutting back on how much you rely on petroleum-based energy for shipping goods.

While using paper-based materials can be a worthwhile alternative to plastics, be sure they are sustainably sourced. These products are usually certified by credible entities such as the nonprofit Forest Stewardship Council (FSC), Sustainable Forest Initiative (SFI), or Programme for the Endorsement of Forest Certification (PEFC).

Sustainable alternatives have fewer toxins than traditional packaging. Biodegradable materials tend to contain fewer toxic or harmful chemicals than plastics and other synthetics. Plus, they’re intended to dissolve into organic matter once used rather than waste away in a landfill somewhere.

Paperboard alternatives such as sugarcane-based substrates also offer brands another way to minimize their dependence on plastics.

Foster brand affinity with eco-conscious consumers. Sustainability is on the minds of most consumers these days. In fact, according to a 2020 article in Environment + Energy Leader, 75% of consumers are content to pay more for a product with sustainable packaging.

In being more ecologically conscious, you can connect with a growing population of consumers eager to support companies taking action on climate change. Brands that are late adopters to sustainability practices are likely to be perceived as less sincere than earlier trailblazers.

Embracing eco-friendly packaging now will enhance your image among consumers.

Dispelling Some Myths About Recycling Packaging

There’s a lot of conflicting information out there regarding what is sustainable and can be recycled, and it’s difficult to know which is ultimately going to help. Let’s dismiss a few recycling myths.

Myth #1: You can’t recycle printed paper and paperboard with UV inks and coatings. In reality, they can be recycled into lower grades, such as corrugated and building materials, and when processed through deinking (floatation and dispersion) facilities, can be recycled into pulp used in tissue and possibly fine paper grade. You can read more about this in an article by Radtech Report, published by the Association for UV and EB Technology.

Myth #2: Printed paper and paperboard decorated with hot stamping and cold foil can’t be recycled. Wrong again. Hot stamping and cold foil applications are recyclable. Depending on the availability of deinking (floatation and dispersion) facilities, they can be recycled into pulp used in tissue and possibly fine paper grade, as confirmed by a report from the Foil and Specialty Effects Association, a resource and education platform committed to sustainable packaging.

Myth #3: Windowed cartons can’t be recycled. Depending on access through local recycling programs, such cartons can actually be broken down to produce lower grades of paper or create building materials, according to the Carton Council, an industry organization committed to growing carton recycling. Consider using cellulose-based window material sourced from cotton and wood that is both compostable and biodegradable.

Myth #4: Most paper and paperboard ends up in landfills. Approximately two-thirds of the paper and paperboard waste in the United States gets recycled, which is among the highest when compared to other materials, per the Environmental Protection Agency (EPA).

These explanations should give you a better sense of which materials are more sustainable or recyclable, but what do consumers look for when trying to determine whether a product is eco-friendly?

How Consumers Recognize Eco-Friendly Packaging

Consumers most often look for a few things to help them identify sustainable packaging. These indicators fit three categories: structural, graphical, and informational.

Consumers seek out structural cues related to the reduction of packaging, choice of materials, reusability, ease of recycling, and whether a package is right-sized for the product. This could include minimal use of plastics or employing folding cartons that neatly fit the contours of the product inside.

Graphic signals often consist of colors, images, and environmental logos. For instance, earth tones and textured paperboard often suggest sustainability to a consumer moreso than metallic or embossed folding cartons. Notably, despite this visual sign, specialty decorative effects do not typically make packaging non-recyclable (see Myth #2 above).

You could also achieve a level of brand synergy by using similar graphics and cues across your materials—a logo on printed marketing collateral and folding cartons, a hashtag showing your green initiatives on social media, or a prominent slogan related to sustainability efforts.

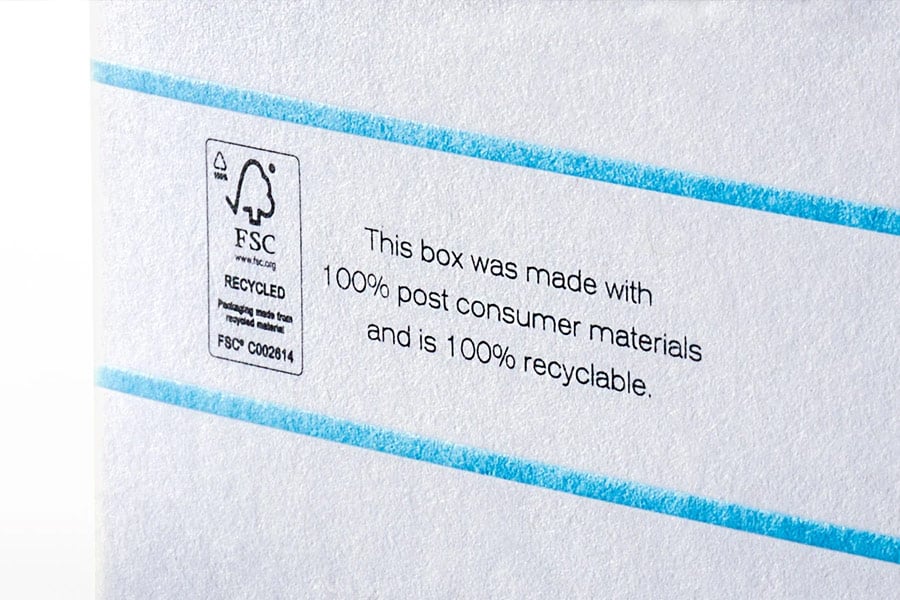

Informational indicators concerned with environmental claims and labeling might be the most explicit for consumers. Wording to the effect of “This is made from post-consumer recycled paperboard” or certification symbols from reputable agencies such as FSC, SFI, or PEFC, help validate your brand in the eyes of consumers.

All of these cues could be combined with sustainable packaging materials. More on those in the next section.

Sustainable Packaging Types

In case you’re struggling to come up with sustainable packaging options, here’s a great place to start.

- Look for paper made from pulp sourced from well-managed forests. FSC-, SFI-, and PEFC-certified paper and paperboard support sustainable forestry. This includes virgin fiber and mixed-recycled content for a variety of papers and SBS grades.

- Try 100% recycled paperboard made with pre- and post-consumer waste. The variety of grades extends well beyond the brown kraft look to include processed, chlorine-free, bright white paperboard for luxury goods.

- Consider tree-free paperboard that uses alternative pulp including bagasse, a waste byproduct of refining sugarcane.

- Thermal mechanical pulp (TMP) multilayer paperboard with a sizing on the outer face makes it suitable for printing. This gives the paperboard a brown kraft surface with an excellent ink holdout.

- Ask your printing and packaging manufacturer if they utilize vegetable-oil-based inks and water-based coatings. These are becoming increasingly popular.

- Consider using cellulose acetate window material for folding cartons, so long as it is certified as 100% compostable and 100% petroleum-free.

- Direct transfer, metalized paperboard that eliminates the plastic film can be easily recycled with other printed papers.

In case you want to get a bit more in-depth about the various paperboard grades, read further.

Choosing the Right Paperboard Grades

You have an abundance of options these days when it comes to sustainable paperboard, with many factors influencing your decision.

Naturally, your selection will vary depending on manufacturer, but you can expect to find the following possibilities. (At least, if the manufacturer is serious about their commitment to sustainability.)

Solid bleached sulfate (Sbs), also known as food board, is made from virgin hardwood and clay coated. With a uniform, smooth white surface throughout the structure, Sbs is generally available in 12- to 24-point calipers. Best suited for offset, flexo, and gravure printing, it has a very smooth surface with moderate durability.

When it comes to converting, Sbs is excellent for cutting and gluing.

Sbs is often used in high-end and premium packaging and the following industries: pharmaceuticals, cigarettes, cosmetics, and food. It’s coated with polyethylene for frozen food packaging.

Solid unbleached sulfate (Sus), sometimes referred to as coated unbleached kraft or coated natural kraft, may contain recycled filler content and must be more than 79% virgin fiber. Sus has a natural brown backside and smooth white surface on the front. Available in 12- to 28-point calipers, Sus has a relatively smooth surface that is good for offset, flexo, and gravure printing.

Sus is very good for cutting and gluing.

The most durable of paperboard, Sus is ideal for heavy-duty packaging in hardware, beverage carriers, and detergents. It is coated with polyethylene for wet strength.

Uncoated unbleached kraft (Uuk), or uncoated kraft boxboard, consists of 85% virgin pine and 15% hardwood kraft fiber, uncoated. It may contain recycled content. In appearance, its front and backside are natural. Available in 12- to 28- point calipers, Uuk is less smooth than other paperboard options. Nonetheless, it’s a good choice for offset and flexo and limited possibilities with gravure printing.

Uuk is good for cutting and gluing.

With relatively high structural strength, Uuk has an industrial “natural” look that suits heavy-duty packaging for hardware, beverage carriers, and detergents. Similarly, it’s coated with polyethylene for wet strength.

Coated recycled board (Crb), sometimes referred to as clay coated news or whiteline chip, is made of 100% recycled fiber, a bleached top, clay coated on one side, and comes with as many as five to 10 plies. Its grey backside helps it stand out. Crb’s print quality results in varied degrees of smoothness, available in 14- to 28-point calipers, making it good for offset and flexo printing.

Crb may not excel with converting, but it remains adequate for cutting and gluing.

Its low to moderate durability means Crb is ideal for multi-purpose folding cartons for cereals, crackers, dry-processed food, and shoe boxes.

Uncoated recycled board (Urb), also known as plain chipboard or bending chipboard, consists of 100% recycled fiber, uncoated. Its earthy grey, light tan color on the front and back clearly suggests sustainability to consumers. Available in 12- to 28-point calipers, Urb has a less smooth surface than other paperboards, nonetheless making it good for offset and flexo printing.

Similar to Crb, it is adequate for cutting and gluing.

Its low to moderate structural strength means Urb is ideal for set up boxes and partitions for an industrial natural look.

Folding boxboard (Fbb), sometimes called tri-plex or manilla board, is made of a bleached top, a groundwood center, and is coated on one side for low density. Its appearance is typically yellowish. Available in 14- to 28-point calipers, Fbb can vary from low- to high-quality printing, often used in offset, flexo, and gravure.

When it comes to converting, Fbb holds the best folding capabilities among paperboards, while being adequately suited for cutting and gluing.

With perhaps the lowest structural strength, Fbb is commonly used for health and beauty products, confectionaries, frozen and chilled foods, and pharmaceuticals. It also offers brands optional pigmented coatings.

As you can see, you have plenty of options available to you. A remaining challenge is determining a comprehensive design strategy for sustainable packaging.

Designing for Sustainable Results

Developing packaging that satisfies your brand’s ecological goals requires a collaborative process with an experienced printing and packaging partner. When working with a manufacturer, here are some things to keep in mind.

Define your objectives. Stating your environmental strategy objectives gives your packaging partner the direction they need to initiate a successful eco-design program. If you’re uncertain, they’ll work with you to define the objectives. These might include concepts such as source reduction, enhanced recyclability, or sustainability by using responsibly sourced materials.

Create the right structure. With folding carton designers in house, your packaging partner should provide a breadth and depth of experience in rightsizing the package, enhancing the potential for reuse or recycling, and developing a structural design to stand out from the competition.

Choose the right materials. Find a packaging partner that works with the industry’s top paper and paperboard suppliers. This will provide you with plenty of options that meet your ecological and economic objectives. Again, to support your environmental claims, look for eco-responsible certifications from the SFI, PEFC, and FSC to assure the responsible sourcing of virgin materials and recycled content. You’ll want to evaluate various inks, coatings, cold foil, and hot stamping choices to enhance recyclability.

Measure the results. Calculating environmental metrics to demonstrate the eco-effectiveness of the design is critical. Be sure your partner has the tools to analyze the impact of changing the folding carton structure or using alternative paper stocks. They will do their part by reducing environmental impact through the purchase of renewable energy certificates that support hydro, wind, and solar power. A partner that’s serious about sustainability in printing and packaging will qualify as an EPA Green Power Partner in support of clean energy.

Go Green with Oliver

We truly are nearing the point where it’s difficult to thrive as a brand without embracing sustainability: Consumers expect it. It can be daunting evaluating all the packaging possibilities and ways in which you may need to restructure production and delivery of your products.

However, by partnering with the right manufacturer, you can be confident you’re taking the steps necessary to become a green leader in your industry.

At Oliver, we’ve combined companies that are masters of their craft and passionate about the packaging and printing industries.

With more than 250 years of collective experience producing folding cartons, marketing collateral, and labels, Oliver is eager to help you achieve your sustainability goals. Contact the Oliver team to discuss your specific requirements and how we can enhance the sustainability of your packaging.