The Oliver Guide to Commercial Label Printing

Contents

- Introduction

- Pharmaceutical Labels

- Health & Beauty Labels

- Food & Beverage Labels

- Stick With Pressure-Sensitive Labels

- Designing Commercial Labels

- Be Sure Your Labels Stick

- Permanent or Removable Labels?

- Acrylic or Rubber-Based Adhesives?

- Performance Factors for Adhesive Labels

- Basics of Label Die Cutting

- Basics of Finishing

- Label Printing Options

- Decorative Effects

- Working With a Commercial Label Printing Expert

Introduction

Customers engage with your company across a mixture of digital channels, but labels are a powerful tool to build affinity, because they’re one of the few embodied encounters people will have with your brand.

Labels serve multiple roles. They inform, providing key ingredient details as well as directions for safe, proper product use. They attract consumers with decorative touches and visual cues. They protect your brand with anti-counterfeiting touches and serialization. In short, a label is more than just a label.

That’s a lot of pressure concentrated on several square inches of substrate.

This guide provides a helpful overview of the proper materials, techniques, and best practices for commercial labels utilized in industries from food and beverage and pharmaceuticals to automotive and electronics.

Pharmaceutical Labels

Labeling plays a uniquely important role among pharmaceuticals. Given these products are consumed by customers or applied to the body, instructions and safety precautions must be contained on both primary and secondary packaging. In case a consumer discards the secondary packaging with its instructive labeling, primary components must contain similar information.

For instance, reflect on how common it is for somebody to remove a cold medicine bottle from the carton it comes in, after its first use, to then place it in a cabinet for extended storage. Consumers later lean on the primary labeling for proper consumption.

Furthermore, pharmaceutical labels must be durable enough to withstand being handled and stored over a long period of time. Vital information on the labels must remain clear and accurate to ensure safe use by consumers.

Lastly, labels can achieve an anti-counterfeiting function by assuring customers pharmaceuticals or medicines haven’t been tampered with, for example, by extending the label over a carton fold to demonstrate whether secondary packaging has been opened already or not.

Health & Beauty Labels

As with pharmaceuticals, health and beauty labels must include ingredient lists, use instructions, and safety precautions on primary and secondary packaging. This safeguards against harmful consumption or ill-advised application of products.

Health and beauty labels traditionally go all-in with decorative effects to attract consumers’ attention. Brands in these industries often want to signal elegance, exclusivity, and style, reflecting what the product inside can do for customers' physical appearance and fitness.

Gloss, cold foil, and hot foil stamping are staples in these industries, routinely employed to give labels additional shine and aesthetic appeal. Lustering labels and packaging ought to correspond with the high-end quality of the products inside. The instant a consumer picks a health or beauty product off the shelf, they see in the packaging what similar positive transformation might occur in their own lives. Give them a glimpse of what impact your product could have on them.

Finally, health and beauty labels must be strong enough to remain legible in a variety of conditions, particularly humid ones. Commonly stored on bathroom counters or next to showers, these products should utilize laminated labels or water-resistant materials.

Food & Beverage Labels

It goes without saying, food and beverage labels should also include vital information on both the primary and secondary packaging. You don’t want to risk consumers abusing your product, misunderstanding its nutritional value, or mistaking how to eat or drink it. Product labels must be compliant with industry safety standards, such as what is outlined in the United States Food and Drug Administration’s labeling guide.

Similarly, in the case of food and beverage, labels will likely need an adhesive that accommodates freezer conditions, temperature changes in and out of a refrigerator, or rotations in a heated microwave. Durable adhesive labels are key here.

And, of course, your label should attract the eyes of consumers. For instance, extended gamut printing enables vibrant colors beyond the traditional four-color printing process, resulting in packaging that really pops. Coupled with window packaging that gives consumers a preview of the food inside and an alluring label, your brand should outshine its competition.

Stick With Pressure-Sensitive Labels

Pressure-sensitive labels have become the industry standard for printing and packaging. Bonding to surfaces with minimum pressure, these self-adhesive labels hold benefits over wet-glued, heat-seal, or water-remoistened labels. The key benefit is their ability to bond to a wide variety of surfaces and substrates, including plastic, paperboard, and other sustainable packaging alternatives.

Plus, they’re super simple to use, requiring minimal machine modifications, preparation, or cleanup. To apply, just pull the liner from the face stock, and press the label directly onto your item.

Pressure-sensitive labels consist of four elements. The face stock is the surface material, which can be made of paper, foil, film, or cloth. Beneath it, the adhesive is designed as a coating layer to adhere to an array of surfaces. Release coating is applied to a liner that regulates the correct adhesion release, enabling you to peel away the soon to be applied label. The release liner protects the adhesive from contamination, and is removed for simple application of the label.

Designing Commercial Labels

Label characteristics will vary depending on your product and how you use them. In designing the right commercial label, keep the following characteristics in mind.

Begin with an accurate drawing of the label, detailing the specific dimensions for the width and length, and the position and diameter of interior cuts.

To determine the right material, you may need to prototype a few designs. As you can imagine, one label material may not partner the same way with every substrate.

Copy will best inform consumers about your product and brand. This is where you can really put your marketing magic to work.

Selecting effective color schemes and imagery will catch consumers' attention. High-end manufacturers will provide you the widest range of color options, and the most vibrant details possible in today’s printing and packaging industry.

If your product or label is going to be exposed to chemicals, moisture, extreme temperatures, or frequent contact with human hands, you’ll want protective coatings to preserve the marketing elements of your labels.

UV clear coat is an opportunity to give your labels a more elegant design. When this liquid coating is applied, whether overall or selected spot coating, it gives your label a hard glossy, satin, or matte finish.

Alternatively, lamination is a protective film that gives labels a high gloss finish with peak resistance to handling, abrasions, and chemicals.

Be Sure Your Labels Stick

Some people feel pressure-sensitive labels can be applied successfully to anything, but that’s not quite true. In fact, self-adhesive labels don’t apply at all to some surfaces. You’ll need to test out labels on your products or packaging before going all-in on a design, with your eye on three performance factors: tack, specific adhesion, and cohesiveness.

Tack refers to the degree to which an adhesive sticks to a surface on first contact, and enables an adhesive to form an appropriate bond with a given material. The tack increases on smooth or heated surfaces (high surface energy) and decreases on rough or cold ones (low surface energy).

The strength of tack is determined by measuring how much pressure is required to peel a label away from a substrate. Labels are typically designated low or high tack.

Specific adhesion defines how well a label remains stuck to a surface after it has been set, usually 24 to 72 hours after initially applied. As you’ll find in testing out labels, an adhesive may bond well with one surface, such as polyethylene, but poorly with another, such as paperboard.

Cohesiveness speaks to the internal strength of the label. A cohesive label will not split easily when it’s removed from a surface. Some brands overlook this element, but keep in mind: Consumers like to reuse packaging or containers, and being able to remove an entire label painlessly can generate some affinity between consumers and your brand.

Permanent or Removable Labels?

Whether you want permanent or removable labels will depend on your marketing needs.

Usually, permanent labels can’t be removed without damaging the label. However, some permanent adhesives have a low tack, enabling them to be removed and repositioned after a short period of time. They then set up after a longer duration. Remember, no adhesive is truly permanent, just less removable than others.

Removable labels will adhere to a substrate while remaining detachable for a limited period of time. The period of use is important. Depending on the surface, some removable adhesives can become more bonded over time—meaning they’ll likely split when removed at a much later date. The rougher a surface the more easily a label can be removed, but also the more difficult for it to adhere.

Acrylic or Rubber-Based Adhesives?

Acrylic adhesives are primarily composed of synthetic polymers, which are inherently sensitive to pressure, while rubber-based adhesives are primarily composed of synthetic or natural rubber. Both adhesives have other components that can be added to modify the pressure sensitivity, as well.

Acrylic adhesives have low-medium tack, low initial adhesion, high ultimate adhesion, and high service temperatures. They demonstrate excellent resistance to plasticizers in plasticized products, such as vinyls, and most solvents. Acrylics also have excellent stability over long periods of time, and especially in the outdoors. With excellent UV resistance, they can also be more costly than rubber-based alternatives.

Rubber-based adhesives exhibit high tack, high initial adhesion, medium ultimate adhesion, and medium-high service temperatures. Unlike acrylics, rubber-based adhesives have poor resistance to most plasticizers and common solvents such as gasoline, oil, and other petroleum derivatives. They display short-term outdoor stability and poor UV resistance. However, they tend to be more economical than acrylic adhesives.

Performance Factors for Adhesive Labels

The success of an adhesive depends on several performance factors. You’ll want to have an understanding of these as you look to select the right printing and packaging partner for commercial labels, determining whether they adhere to these best practices or not.

Composition

Again, how well a label sticks depends on the composition of the substrate, be it plastic, paperboard, or an alternative material. Plastic substrates (Polyethylene, Polypropylene, etc.) are not readily compatible with straight acrylic-based adhesives, and consequently, may not provide the destructibility of a rubber-based adhesive.

Texture

Pressure-sensitive adhesives require good contact with the substrate surface to obtain adhesion. A substrate with rough texture will reduce the amount of surface area the adhesive will be able to contact, reducing the level of adhesion. Rough corrugated boxes, pebbled plastic computer cases, and wooden pallets are all examples of possible problem areas. Label materials with a heavier coating weight or a more aggressive adhesive are available to provide the required adhesion level.

Shape

The shape of the substrate, along with the size and stiffness of the label, must be considered to ensure proper end-use performance. Pressure-sensitive adhesives require a short period to flow into the surface of the substrate and obtain maximum adhesion.

If a stiff label is being applied to a curved surface, the stiffness or memory of the label may cause the label to lift from the substrate before the adhesive has had a chance to adhere to the surface. Rougher substrates will aggravate the situation. Typical solutions will be to use either a more aggressive adhesive or a more flexible label.

Cleanliness

Less of a design issue, and more the responsibility of your printing and packaging partner, the cleanliness of the substrate surface when the label is applied will affect its ultimate adhesion and the success of the application. Contamination from dirt, oils, frost, and other foreign elements prevents the adhesive from contacting the surface. When selecting a manufacturer, be sure to ask them about potential contaminants in their process that could compromise label adhesion.

Other contaminants present during the manufacturing of the substrate, such as mold release agents on blow-molded plastic products and plasticizers in vinyl products will affect the adhesion or reduce the life of the label through adhesive deterioration. All substrates should be clean and free of all contamination. In situations where contaminants are inherent in the manufacturing process, special adhesives may be available to overcome the problem.

Temperature at Application

Verify with your manufacturer whether they apply the label at the proper temperature levels. The temperature of the substrate at the time the label will be applied can affect its ability to adhere to the substrate. Pressure-sensitive labels require the adhesive to flow into the pores of the substrate.

If the temperature at the time of application is below the freezing point of the adhesive, the adhesive will lose its ability to grab the surface and edge lift or fall off. Typical minimum application temperatures are between 40 to 50 degrees Fahrenheit. Special adhesives can accommodate application temperatures down to minus 10 to minus 20 degrees Fahrenheit.

Environmental Conditions

Paper label materials are affected by moisture either through direct contact or humidity in the air. Moisture can cause the paper to deteriorate, resulting in a loss of print contrast and barcode scanning.

For label applications requiring resistance to moisture, special materials are available. These include resin and latex impregnated papers for limited exposure, and vinyl, polyesters, and other plastics for maximum exposure. Many of the label materials can be laminated with a clear polyester to increase the durability of not only the label, but the printed image, as well.

Expected Useful Life

The environment the label will be exposed to during its life will play a role in the selection of the appropriate label material. Applications requiring resistance to grease and oils, as in labels for the automotive industry, may need either a latex impregnated paper or vinyl label. Applications that expose the label to excessive levels of abrasion may demand either a stronger paper or a plastic. Long-term exposure to high heat (above 120 degrees Fahrenheit) will cause most label materials to deteriorate, and may require a special product.

It’s important to understand the role each of these factors plays in label performance—however, your best bet is to test how well your commercial labels perform on packaging under real conditions before pushing them to market.

Basics of Label Die Cutting

Pressure-sensitive roll labels are die cut with tooling specially configured for their designs, layout, and materials. Dies can create styles such as square corners, round corners, circles, bursts, ovals, special shapes, individual sheets, etc. Your manufacturing partner will likely offer most, if not all, of the following die-cutting options.

Solid Rotary Dies

Working with a hardened steel cover, the rotary die is aligned to the specified layout, depth, and other requirements. Solid dies provide a precise cut, are durable, and have a long run life.

Flexible Dies

Flexible dies are chemically etched to form the depth, layout, and edge requirements of thin steel sheets with chrome plating. The flexible metal sheets are mounted to magnetic cylinders to register with the printed graphics. Given the nature of the materials used, these dies are less expensive and less durable than solid rotary dies.

Die-Cut Labels

Die-cut labels are the most common style of cutting labels. They can be a round-corner rectangle, circle, oval, burst, or other special shape. A steel die with multiple cavities tooled to the size and shape of the die cut is required. This die then cuts through the face stock and adhesive but not through the liner. The matrix (waste) around the die cut is removed, leaving the label on the finer ready for application. Die-cut labels are easily removed from the liner, and less likely to lift when subjected to extreme environments. Die-cut labels are usually supplied on a roll. Machine-applied and most machine-imprinted labels are die-cut style labels.

Die-Cut Pin-Feed Labels

Pinfeed labels are commonly used to add variable, computer-generated information. They are die-cut labels with the addition of pinfeed holes cut into the liner for use with a dot matrix printer. These can be delivered fan-folded, or on rolls.

Butt-Cut Labels

This is a rectangular-shaped, square-corner label separated from each other by a single, straight blade cut. There are no gaps or extra liners around the label. A butt-cut blade slices through the face stock and adhesive, but not the liner. There are no bleeds on butt-cut labels, which are delivered on rolls.

Sheeted

This rectangular-shaped, square-corner label is sheeted individually using a straight-edge blade. A sheeter blade cuts through the face stock, adhesive, and liner. A top or back score is added to crack and peel the liner from the label. There are no bleeds on sheeted labels, which are delivered as individual labels.

Basics of Finishing

Labels can be finished in different forms, the most common being rolls, sheeted individually, or fan folded. The way your labels are finished and packaged will depend upon how they are applied, and used.

Rolls

Labels finished are spooled or rolled on a core. The standard roll has a 3” core and is wound to a 12” diameter, but other core sizes and finished roll dimensions can be configured to meet your application needs. Common types of rolled labels include product and promotional labels, shipping labels, thermal transfer, and direct thermal labels.

Sheeted

These are individual single-sheet labels usually containing a back or top score. Sheeted labels can be bulk packed, poly bagged or shrink- wrapped. Bumper stickers are an example of sheeted labels.

Fan Folded

Die-cut labels with a perforation across the liner are folded back and forth along the perforations, creating a stack of labels. Most computer pinfeed labels are delivered fan folded.

Label Printing Options

Flexographic and digitally printed labels are the two available printing options. Determining which process is best suited for order requirements will depend on the number of colors, type of labels, decorating treatments, finishing requirements, and print run timeline.

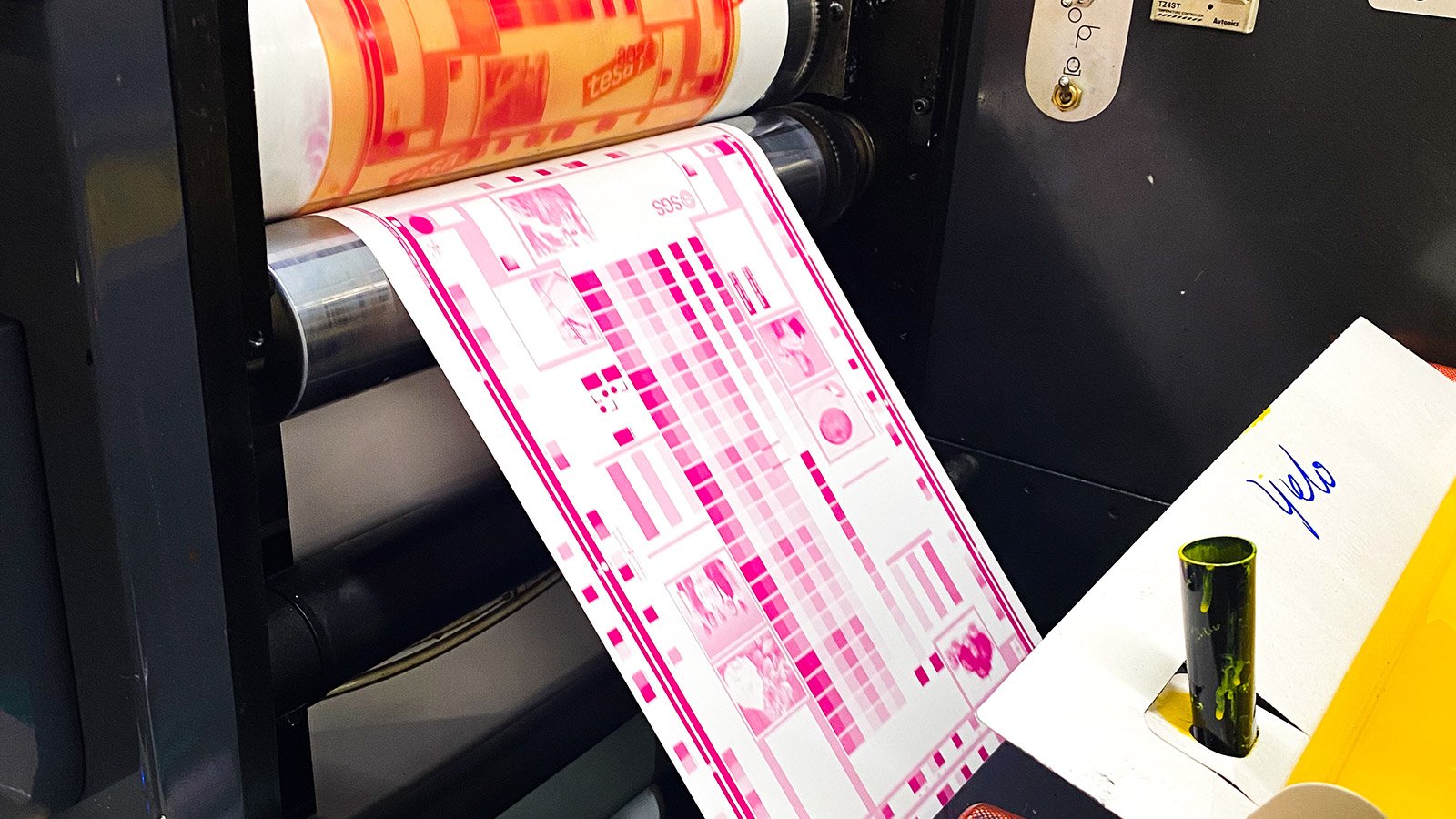

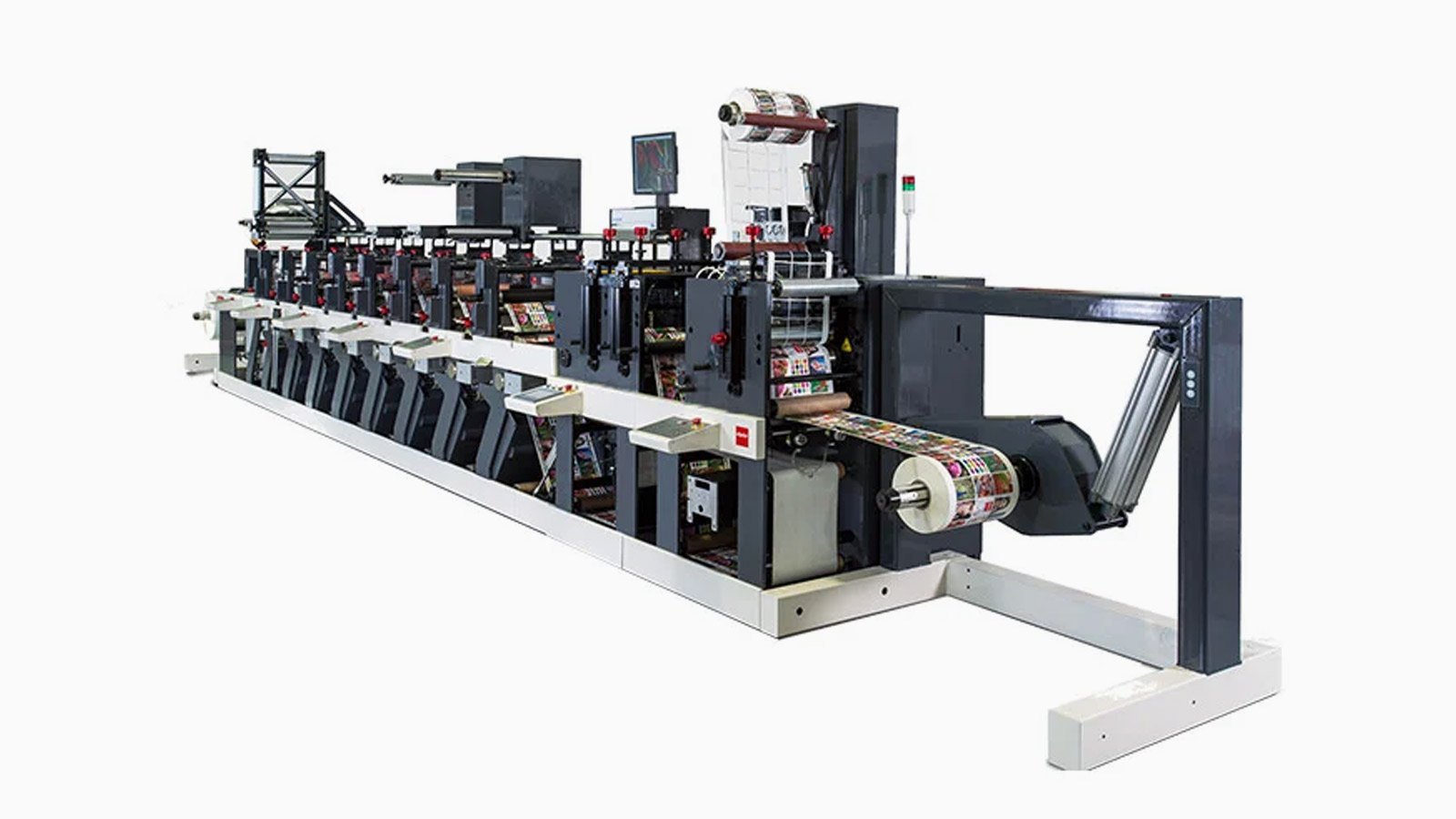

Flexographic Printing

In simple terms, flexography or “flexo” printing gets its name from the flexible plates used in the printing process. These are most commonly made from a photopolymer material that bends around the narrow cylinders used to print roll labels. The presses have multiple print stations to apply inks or coatings and inline cold foil, turn bar assembly for back-side printing, die cutting, and more.

Flexo labels provide rapid speed at reasonable cost, particularly for large orders on short lead times. Since flexographic printing can be combined with other processes, such as embossing, it can integrate a high degree of design flexibility.

Digital Printing

With no plates to create, and very little setup of the machine, a digital press eliminates most of the make-ready hours required with conventional flexographic presses. The digital process does require a secondary finishing operation, however.

A more recent innovation in printing, digital comes with a variety of advantages, including:

- High resolution, even for tiny details and small print

- Crisp type and superb clarity

- Photographic-quality imagery

- Rapid turnaround, ideal for short runs

- Variable data and personalization during the print run

- Accuracy and precise print of each digital label, for absolute consistency

Decorative Effects

We’ve glossed over decorative effects a bit already, but let’s take a deeper look at the array of options available.

Tactile Coatings

Designed to be soft-feel or soft-touch, textured, and raised, tactile coatings transcend visual engagement with the consumer by stimulating additional senses to capture their attention.

Motion Coat

A form of raised UV coating, motion coat is applied in a pattern using a printing plate to give an image a visual sense of movement on the substrate.

Glitter & Pearlescent Coatings

These use small reflective particles dispersed in a base of clear UV coating to add shimmer and depth to an image.

Strike-Through & Reticulating Varnish

Although more costly, these coatings provide superior rub resistance and higher gloss. Both aqueous and UV coatings form the basis for delivering more specialized versions to enhance the look of the label.

Gloss

In general, gloss is used to express the ability of a surface to reflect direct light. It can be used with aqueous and UV coatings.

Foil

Once the purview of luxury brands and deluxe confectionary companies, foil has become more common during the past two decades, due to its increasing cost-effectiveness.

Hot Foil Stamping

A dry transfer process in which foil is dispensed from a roll and applied using heat and pressure, hot foil stamping leaves a clean, luxurious finish.

Cold Foil

Whether in a sheet-fed lithographic or flexographic process, cold foil is dispensed from a roll-mounted inline on the printing press, and a UV adhesive is printed on the substrate in your desired pattern. Cyan, magenta, yellow, and key (CMYK) or Pantone Matching System (PMS) colors can be applied to traditional silver or gold foils for customization.

Embossing

Using pressure and metal die to create a design, embossing is the creation of a raised image on a flat material.

Debossing

Conversely, debossing involves lowering an image or text into a substrate to create tangible depth.

Extended Gamut

Referring to an expansion of the colors that can be achieved beyond traditional, four-color process printing (CMYK), extended gamut printing significantly expands the color gamut and ability to achieve richer and more vibrant colors.

Working With a Commercial Label Printing Expert

Getting your label designs right involves a lot of moving elements, including the right packaging materials, appropriate adhesives, and visual elements that deliver consistent brand messaging. By collaborating with an experienced printing and packaging partner, such as Oliver, you’ll have a supportive guide every step of the way.

Oliver’s team of experts has a combined three centuries of history in helping brands elevate their packaging and printing. Developing an effective label demands the balance of attention-grabbing design, with an exacting adherence to industry safety standards for displayed information, such as the FDA’s current Good Manufacturing Practices (cGMP).

Throughout the years, Oliver has fine tuned the process to help streamline your printing and packaging so you can continue developing products your consumers love.